Vibratory Loss-in-Weight Feeders

Geomate™ Mass Flow Feeder

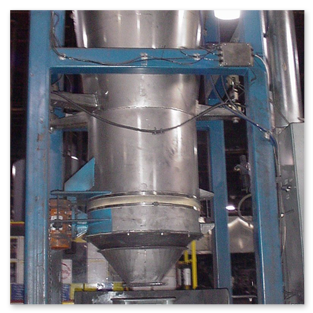

CMT Process Solutions offers mass-flowing vibratory weigh feeders built around 3Sigma’s exclusive GeoTray™ FeedTray and MassMate™ Mass Flow Hopper, delivering precise, reliable feeding for a wide range of dry bulk materials.

These feeders provide true mass flow, high-frequency dribble feed, instant on/off control, and a no-moving-parts feed tray, resulting in exceptional accuracy, repeatability, and minimal maintenance. With no bearings, seals, or wear components, downtime and operating costs are significantly reduced.

The GeoMate™ Vibratory Weigh Feeder utilizes a simple, robust platform with field-changeable GeoTray™ configurations tailored to material flow properties, allowing one design to handle a broad range of products. Proven across industries from aggregates and chemicals to food, pharmaceuticals, and recycling, these feeders handle capacities from a few ounces per hour to multiple tons per hour.

Geomate™ Mass Flow Feeder

Features and Advantages

Features

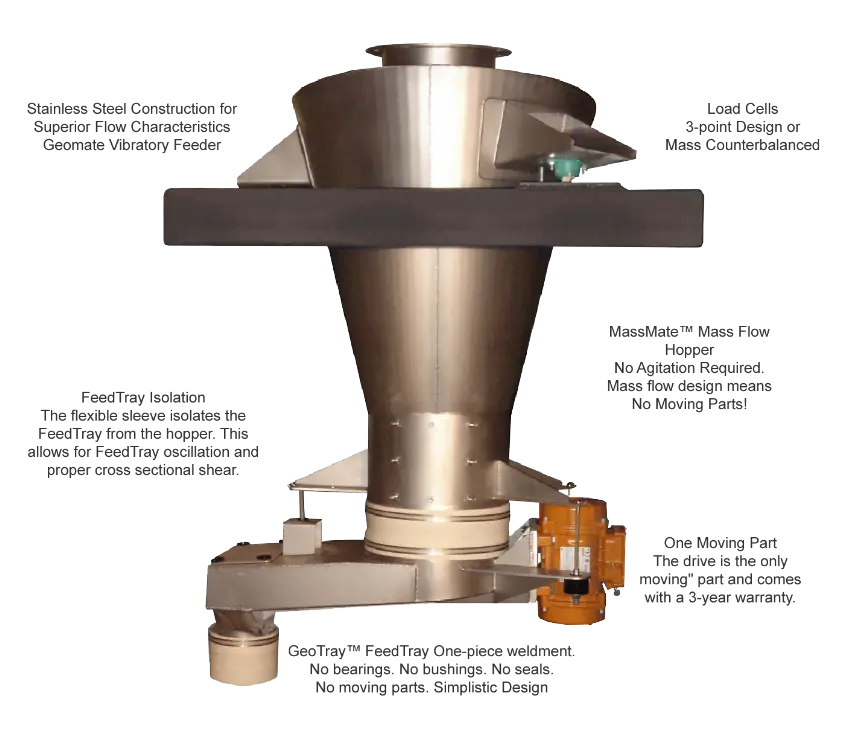

The Geomate® Mass Flow Feeder is engineered for reliable, low-maintenance performance in demanding bulk material handling applications. Constructed entirely of stainless steel, the system delivers superior flow characteristics while resisting wear, corrosion, and material buildup.

The feeder incorporates a precision load-cell weighing system, available in either a 3-point design or mass-counterbalanced configuration, ensuring accurate, repeatable mass flow measurement across a wide range of bulk solids.

At the core of the system, the MassMate™ Mass Flow Hopper is designed to promote true mass flow without the need for mechanical agitation. This design minimizes material hang-ups, reduces segregation, and eliminates unnecessary wear points. With **only one moving component—the drive unit—**the system offers exceptional reliability and comes standard with a 3-year drive warranty.

Material discharge is handled by the GeoTray™ FeedTray, featuring a robust one-piece welded construction. The FeedTray contains no bearings, bushings, seals, or internal moving parts, dramatically reducing maintenance requirements and eliminating common failure modes found in conventional feeders.

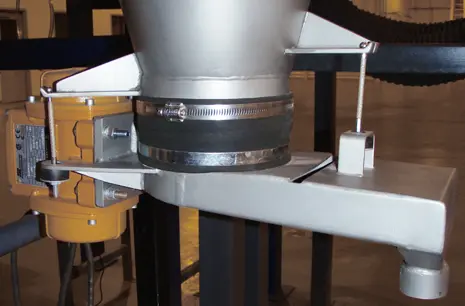

A flexible isolation sleeve separates the FeedTray from the hopper, allowing controlled tray oscillation and promoting proper cross-sectional shear of the material bed. This isolation ensures consistent discharge, improved flow uniformity, and precise feeding performance—even with challenging bulk materials.

Advantages

Dependability & Maintenance

The GeoMate™ vibratory weigh feeder is engineered for long-term reliability with no internal moving parts. Its mass flow–based vibratory design eliminates the mechanical components commonly found in screw feeders, including screws, sprockets, bearings, bushings, shafts, seals, agitators, motor brushes, and multiple drive assemblies. This simplified architecture significantly reduces maintenance, downtime, and failure points.

The GeoMate™ feeder performs reliably with abrasive materials, ultra-fine powders (such as magnesium and iron oxides), and cohesive products (including clays), without degradation in performance. The system supports both loss-in-weight and gain-in-weight operation, enabling accurate gravimetric feeding as well as flexible volumetric feeding modes.

The GeoMate™ Feeder Tray isolated from hopper using a flexible sleeve

Abrasive Materials

In conventional auger systems, abrasive materials rapidly wear feed screws—often rendering them unusable within months and driving frequent, costly replacements. The GeoMate™ vibratory feeder avoids material compaction and surface-to-surface friction by not forcing product against a rotating screw or discharge tube, effectively eliminating abrasive wear and extending equipment life.

Fine Materials

Ultra-fine products (-100 to -325 mesh) commonly migrate past seals in conventional screw feeders, eventually causing binding, wear, and premature failure. While air purges and specialty seals may delay the issue, they do not eliminate it. The GeoMate™ vibratory feeder contains no shafts, seals, or mechanical unions, completely removing this failure mode.

Fibrous Materials

The patented rod tray design effectively handles challenging fibrous materials, including steel wool, steel fibers, and similar products, without wrapping, bridging, or plugging.

Cohesive Materials

Cohesive products often compact and harden inside screw feeders, leading to binding, heat buildup, screw deformation, and costly downtime. The GeoMate™ vibratory feeder eliminates these risks by removing internal rotating components, ensuring consistent flow without material compaction or mechanical seizure.

Accuracy

The inherent design of the GeoMate™ vibratory weigh feeder delivers significantly higher batch accuracy than conventional screw feeders. Consistent output at both high-speed and dribble-feed rates produces a predictable and repeatable material “free-fall” profile. This consistency, combined with the control system’s preact compensation and instant-off capability without material plopping, results in superior final batch accuracy.

Investment

Initial investment for a GeoMate™ vibratory weigh feeder is comparable to that of a traditional screw feeder. Over the long term, total cost of ownership is substantially lower due to the absence of wear components. Unlike screw feeders—which require ongoing replacement of screws, seals, bearings, sprockets, and motor components—the GeoMate™ feeder has virtually no consumable parts and is backed by a 3-year warranty.

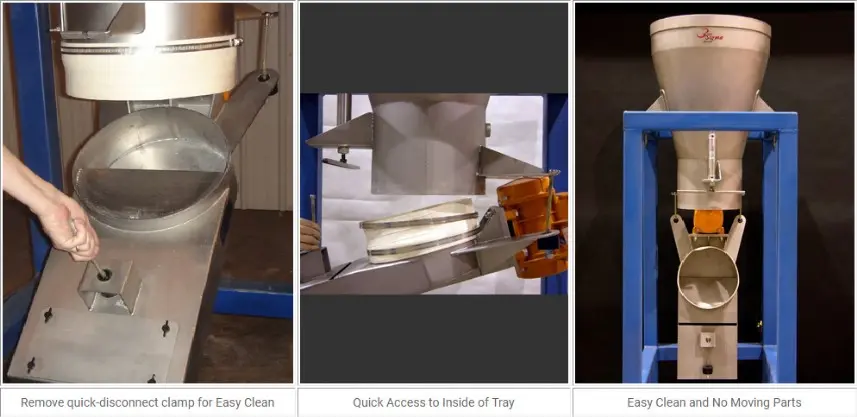

Cleaning

The GeoMate™ vibratory weigh feeder is designed for fast, thorough cleaning. A single quick-disconnect clamp allows the feed tray to swing open, providing full access for inspection, washdown, or product changeover.

Safety

With no internal moving parts, the GeoMate™ vibratory weigh feeder minimizes pinch points and mechanical hazards, significantly reducing the risk of operator injury and improving overall plant safety.

Photos

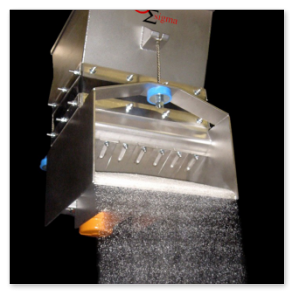

BrickMaster™ Feeder

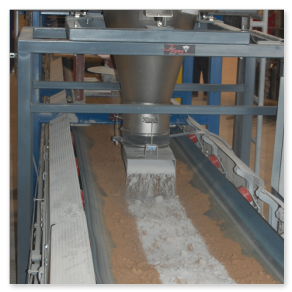

CMT Process Solutions provides complete brick mixture and coating systems, including raw material compounding, mixing, conveying, coating, and reclamation. Systems are available in manual, semi-automatic, and fully automated configurations to match plant capacity and operational requirements.

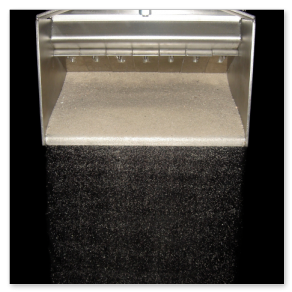

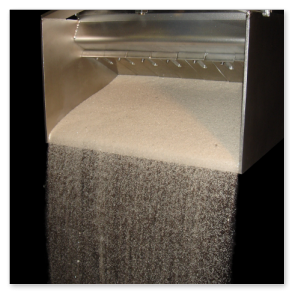

Designed to handle sand, clay, and shale mixtures, CMT systems utilize true mass flow feeding to eliminate operator intervention while delivering consistent, uniform application. The low-profile feeder design mounts less than 1 inch above the brick line, minimizing dust generation and improving plant cleanliness.

Coating width adjustments can be made in minutes, while a 100:1 turndown ratio allows precise control across a wide range of production rates. Systems are available in inline or bias-cut configurations and support both volumetric and gravimetric control.

All systems are backed by an industry-leading 3-year warranty.

Compounding Systems

3Sigma provides fully integrated automated compounding systems that precisely deliver raw ingredients to the mixer in a controlled, sequenced process. These systems improve consistency, reduce operator intervention, and ensure repeatable mix quality.

Mixers

A full range of industrial mixing solutions is available to meet specific production and cycle-time requirements. Options include ribbon blenders, hybrid ribbon mixers, and high-intensity blenders capable of completing a full batch in under one minute, supporting both low- and high-throughput operations.

Conveying

3Sigma offers multiple material conveying solutions to efficiently transfer mixed ingredients to the BrickMaster™ coating feeder. Systems include dense-phase pneumatic conveying for fully automated, dust-controlled operation, mechanical conveying for shorter distances, and tote-based handling where flexibility is required.

Reclaim Systems

Header reclaim systems are engineered to eliminate material waste, dust, and manual handling. Available in both mechanical and pneumatic configurations, these systems can deliver rapid ROI—often paying for themselves in as little as three months. A recent installation reduced raw material usage from 31,300 lbs per 8-hour shift, generating thousands of dollars in weekly savings.

Email us at info@cmtnc.com or Fill Out the Contact Form Below