Super Sack Handling Equipment

Super Sack Handling Equipment for Bulk Bags

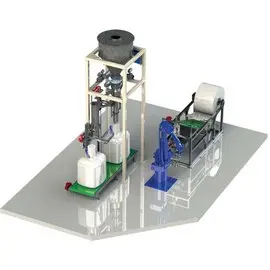

Complete Super Sack Handling Equipment Solutions for Emptying, Filling, and Disposing Bulk Bags

Carolina Material Technologies prides itself in being one of the nation's top Super Sack Handling Systems Integrators for Bulk Bags and FIBC Super Sacks. Whether you are looking to empty, discharge, fill, or dispense bulk bags, our experts will consult with you to design and provide a bulk bag handling system that fits your needs and integrates seamlessly into your existing plant.

A safe and efficient super sack handling system is critical due to the increased labor and associated risks that occur when lifting heavy super sacks that often weigh over 2000lbs. Our engineers spent countless hours designing an operator-friendly system with safety in mind. Our Selection includes 3Sigma Bulk Bag Unloaders, Bulk Bag Dispensers, and Super Sack Fillers.

þ Bulk Bag Unloading & Filling Systems

þ Bulk Bag Compactors

þ Maximum Dust Control

þ 3Sigma Flow Optimizers

þ Engineered Turnkey-Systems

þ Customize to Fit Your Needs

Super Sack Handling Systems

Super Sack Unloaders

One of the most important aspects of a Super Sack Handling Equipment System is the method that you choose to unload the material from your Bulk Bags. Choosing a quality Bulk Bag Unloader that properly discharges your product to downstream equipment can save you thousands of dollars on material costs. That's why we chose to offer the best bulk bag unloader on the market. 3Sigma's newest bulk bag unloading and filling technologies allows you to discharge any material. 3Sigma offers three different models: Fork Truck Loaded Unit, Integral Hoist and Trolley Unit, and a Short-Frame Model (Client Supplied Ceiling Mounted Hoist and Trolley Unit). Each unit can be modified to include the following features: Shape-It™ Vertical Vibration, Massage-It™ Agitation System, Contain-It™ Access Chamber, Close-It™ (Stops material flow by closing bag spout), Clamp-It™ (Pneumatically operated clamp to ensure total containment by sealing the bag spout to the Tube-It™ discharge tube), and Dust Collection Systems. Contact one of our bulk handling system specialists for more information on our bulk bag unloaders.

RECENT PROJECTS: Bulk Bag Unloader to Twin Screw Conveyor

This Bulk Bag Handling System features 3Sigma's Shape-It™ Vertical Vibration. This model boasts an ultra heavy-duty dish made of ¼” plate steel that supports the super sack in place. The operator then accesses the bulk bag spout through the door of the dust-tight Contain-It™ Access Chamber, and clamps the spout to the Clamp-It™ where the super sack is made ready for discharge. The operator then uses the Close-It feature to pinch the bulk bag closed to ensure that material does not begin discharging once the bag is un-tied. The operator then unties the bag, closes the door, opens the Close-It™ valve, and turns on the Vibration on the Shape-It to begin discharging the material. The material is then discharged into a twin-screw conveyor where the product is transferred to the next phase of the process.

RECENT PROJECTS: Multiple Bulk Bag Unloaders to Pneumatic Conveying System

This Bulk Bag Handling System features 3Sigma's Massage-It™ Paddle Agitation. This model boasts ultra heavy-duty pipe agitators that “massage” the material in the super sack for optimal flow. These bulk bag unloaders are part of a complete process line system that CMT provided, including the storage silos and pneumatic conveying system. The bulk bag handling process involved the operators accessing the bulk bag spout through the door of the dust-tight Contain-It™ Access Chamber, and clamping the super sack spout to the Clamp-It™ where the bulk bag was made ready for discharge. The operators then use the Close-It feature to pinch the bulk bag closed to ensure that material does not begin discharging once the bag was un-tied. The operators then untied the bag, closed the door, opened the Close-It™ valve, and turned on the paddle agitation to begin discharging the material. The material was then discharged into a bottom hopper where rotary valves introduced material into the pneumatic conveying line, where the material was then transferred to the next phase of the process.

Super Sack Compactors

Disposing your bulk bags after the unloading process is also an important step in your Super Sack Handling Equipment System. Our Bulk Bag Compactor Machine can compact 7-10 super sacks into a 2' x 1' Bale in a matter of minutes, making bag disposal and recycling easier than ever. Not only does it compact Super Sacks, but also a variety of Films, Cardboard packaging, Plastic Foam Packaging, Paper, Plastic Foams, Fleece Materials, and much more! No more dusty bulk bags or product waste laying around taking up valuable factory space. With our portable Bulk Bag Dispenser, you can save valuable time, space, and effort by disposing of your recycling materials at the bag discharging station. We offer two different models of the Bulk Bag Dispenser Machine: RC 1650, RC 1655. Contact one of our bulk handling system specialists for more information on our bulk bag compactors.

Super Sack Fillers

Many super sack handling equipment systems consist of Bulk Bag Fillers. Carolina Material Technologies provides a full range of 3Sigma Bulk Bag Fillers that weigh and fill different types and sizes of FIBC bags with powders, granules, plastics, seeds, pellets, etc. Product is usually transferred into the bag using gravity, pneumatic conveyors, screw augers, or feeders. Super Sacks are filled and weighed in real time through a scale that is connected to a PLC. Our bulk bag fillers and filling stations can fill super sacks made from lined or unlined poly woven material weighing anywhere from 1000 to 4000 pounds at rates of 5 to 70 bags per hour. We offer Manual systems, Semi-Automatic and Fully Automated systems, as well as volumetric and gravimetric Bulk Bag Fillers. From low capacity bulk bag fillers to high-capacity automated bulk bag systems, we have a proven solution to meet your requirements. We also offer Bulk Bag Fillers with cone table densification systems and auto height adjustment. Contact one of our bulk handling system specialists for more information on our bulk bag fillers.

Contact Us For a Quote

Email us at info@cmtnc.com or Fill Out the Contact Form Below