Dense Phase Pneumatic Conveyors

CONVEY YOUR MATERIAL WITH DENSE PHASE PNEUMATIC CONVEYING

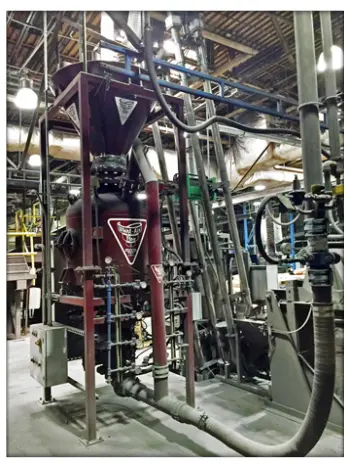

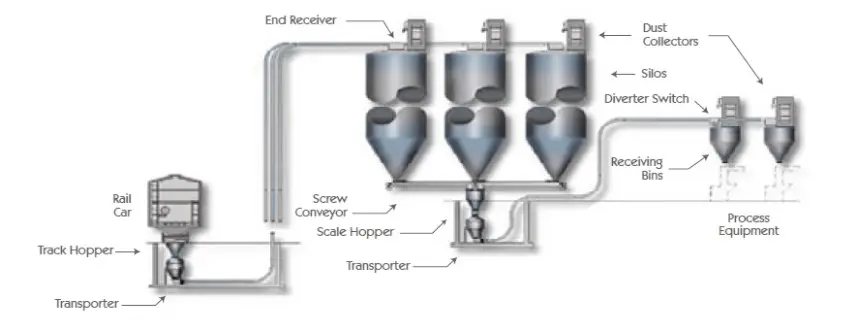

Whirl Air Flow provides a full line of Dense Phase Pneumatic Conveying Systems in order to meet your needs, including Dense Phase Pressure Conveying systems, and Dense Phase High-Vacuum Unloading Systems. Dense Phase Pressure Conveying systems are used in applications that require transporting hard to handle materials. Dense Phase Pressure Conveying Systems unload materials from a rail car to silos with subsequent on-demand delivery of products to in-plant process bins.

Overview

Dense Phase Pneumatic Conveying is a popular method used to move solid materials in gas or air suspension using a high solid to air ratio and is a specialty of Whirl Air Flow. In contrast, dilute phase pneumatic conveying uses a low solid to air ratio.

VACUUM OPERATION

Vacuum operation utilizes high capacity vacuum pumps to convey materials from a feed hopper or silo to a vacuum hopper where the air and product are separated by a filter. When the hopper is filled, the vacuum is isolated and the material is discharged into the destination silo. Material is conveyed through the pipeline at a controlled low velocity, usually in a fluidized state to minimize pressure drop and friction. Valves and sensors are used throughout the system to control the applied vacuum, product fluidization settings, velocities at all parts of the system. This ensures reliable conveying of material. Vacuum systems are ideal for friable granular and powder or pellet abrasive materials.

PRESSURE OPERATION

Pressure operation uses PD blowers or compressed air or gas to send materials through the pipeline. At the destination, air and material are separated by a filter or other system. We offer two options for pressure operations: batch dense phase pressure and continuous dense phase pressure. Batch dense phase pressure allows the material to be transported in distinct batches at the starting point and/or destination and is idea for materials that may degrade from sliding or rolling, are abrasive, require lower velocities, or where material segregation is a concern. Continuous dense phase pressure systems utilize high-pressure rotary valves and compressed air to move materials at lower relative velocities on a continuous basis from starting point to destination. Controls vary airflow and regulate pressure and continuous systems are ideal when materials may be easily damaged by interruption in flow. These systems are also capable of sending materials from a single or multiple points to multiple destinations.

Features

- Pressure conventional: Whirl-Air Standard Transporters convey most free flowing materials in a fill,close, seal, pressurize and convey cycle. The cycle ends when both the transporter and conveying line have been fully evacuated. Full evacuation is detected by a pressure sensor.

- Pressure full line: These systems are designed for use with materials where very abrasive or minimal to zero breakage is a concern. "Keep Full" systems minimize turbulence within the conveying line by evacuating only the transporter before beginning a new cycle. A sensor within the transporter detects empty. Compressed air inside the transporter is then vented to a dust collector prior to starting a new conveying cycle.

- Deep Vacuum:These systems are designed for use with materials where product breakage or system wear is a concern concern. These system also do not require pits in rail unloading applications.

- Deep Vacuum/Pressure Dense-Phase Conveying Systems:Dense-phase rail unloading systems allow automatic unloading of multiple railcars at the same time. This system requires no pits. The extremely low conveying line velocities of these systems are best suited to handling fragile or abrasive materials where product breakage or system wear is a concern. This design allows conveying of materials over extended distances.

Email us at info@cmtnc.com or Fill Out the Contact Form Below