Cardboard Baler Compactor

Cardboard Baler Compactor for Recycling Waste

Automatically Roll, Compact, and Shrink Wrap Cardboard Waste in Minutes

Our Cardboard Baler Compactor Machine streamlines packaging waste management by automatically rolling, compacting, plastic-wrapping, and cutting cardboard into neat, manageable bales. Designed with built-in mobility wheels, it allows you to dispose of recycling materials conveniently at any unpacking location—saving valuable time, space, and labor.

With its user-friendly design and efficient operation, the Cardboard Baler Compactor makes disposing and recycling cardboard waste faster, cleaner, and easier than ever before.

þ Compacts Cardboard into Small Bales

þ Decrease Labor / Increase Sanitation

þ Increase Valuable Factory Space

þ Decrease Labor / Increase Sanitation

þ Increase Valuable Factory Space

þ Advanced Safety Features

þ 1x2' Bales Allow for Easy Handling

þ Portable Units Available

Cardboard Baler Compactor Features

Maximize your warehouse space and cut costs with our advanced cardboard recycling solution. This powerful system automatically compresses and rolls cardboard waste into tightly packed bales, freeing up valuable floor space while streamlining your recycling process. Its compact, mobile design fits seamlessly into any facility, improving hygiene and sanitation by reducing clutter and dust. Built with advanced safety features to protect your team and engineered with heavy-duty strength, it delivers top performance without taking up unnecessary room. The result? Significant savings on labor, storage, and transportation — all while creating a cleaner, safer, and more efficient operation.

- Free up valuable warehouse space by compacting bulky cardboard waste

-

Automatically compresses and rolls recyclables into neat, transport-ready bales

-

Compact, mobile design integrates easily into any facility

-

Enhance plant hygiene and improve overall sanitation conditions

-

Built-in advanced safety features keep operators protected

-

Delivers heavy-duty performance without wasting space

-

Achieve major cost savings in labor, storage, and transportation

Photo Gallery

Technical Information

Technical Specifications

-

Application: Designed for compacting super sacks and similar materials. Equipped with electrical components rated for 480 V (3 PH + N + PE) / 60 Hz.

-

Drive System: Heavy-duty three-phase gear motor (3 kW, 480 V / 60 Hz, IP54, IE3 efficiency class) mounted on a reinforced base frame with robust main drive via roller chain.

-

Accessibility & Maintenance: Inspection doors on side and rear walls provide easy access for cleaning, servicing, and maintenance.

-

Safety Features:

-

Inspection doors and flaps secured with safety interlock switches.

-

Protective safety panels at both the feed table and bale ejection zone.

-

Additional flashing light to indicate “bale full.”

-

-

Control System:

-

Electrical control panel with main switch and reset button positioned on the feed side.

-

Reverse run functionality with automatic overload protection.

-

Potentiometers for adjusting wrapping sequence and operating time.

-

Fully automatic control of wrapping, film cutting, ejection door, and bale discharge.

-

Operator control unit at the feed table with “start,” “stop,” and “reverse run” buttons, plus selector switches for operation mode and bale diameter. Manual switch for bale ejection door and alarm indicator for “bale full.”

-

Separate multi-function display with continuous fill-level indication, operating hour counters (daily and lifetime), and bale counters.

-

Bale counter located at bale ejection point.

-

-

Material Handling Features:

-

Feed table for manual loading of bulk bags or recyclable material.

-

Integrated dust hood above feed table with connection port for central dust extraction.

-

Dust collection drawer positioned below machine.

-

-

Construction & Finish:

-

Mounted on castors for mobility.

-

Supplied with 3-meter power connection cable.

-

Machine finish: RAL 7016 (framework) and RAL 7038 (covers & doors).

-

Includes stretch wrap tying system with one roll of stretch wrap film fitted.

-

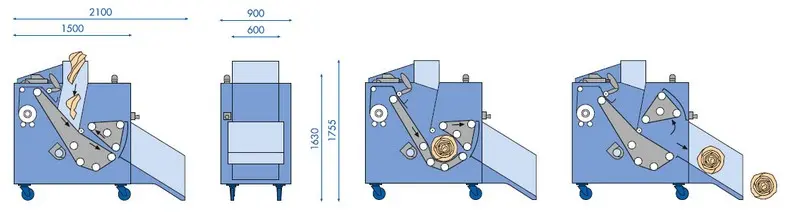

Description of working method

After sorting out the bulk bags or recycling material, it can be placed on the table of the machine. Insert the material into the chute, allowing the conveying belt to grasp it and pull it into the compacting chamber and where it is then rolled by the machines rotating action of two belts. As more and more bulks bags or material is inserted into the chute, the two conveying belts form a cylindrical bale where the recyclable material or waste is compacted. The material remains compacted inside the machine, allowing the compacting process to take place on-demand and allowing the operator to insert bags as needed. The compacting progress is displayed continuously via an LED display. After achieving the pre-selected bale size (Model RC 655 has three bale diameters that can be selected), the bale wrapping is initiated by pulling the plastic wrap and inserting it into the feed intake chute. The compacted bulk bags (or material) are then automatically wrapped with the plastic film. After the wrapping process is completed, the plastic film is automatically cut by the machine. The baling compartment is then opened with a push of a button on the operating console and will close again automatically after having ejected the compacted bale. The RC 655 fully automates the cutting process, as well as ejecting the compacted bulk bags.