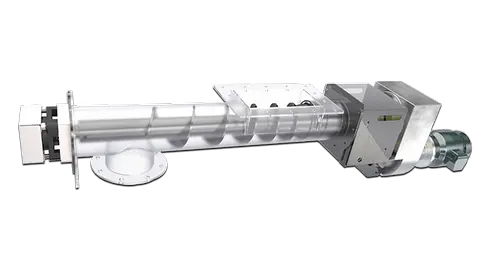

Screw Conveyors & Augers

Screw Conveyors and Industrial Augers for Material Conveying

Screw Conveyors and Industrial Augers for Material Conveying

Horizontal Screw Augers, Vertical Screw Conveyors, Flexible Screw Conveyors, and Olds Elevator Screws

Screw Conveyors and Industrial Augers are some the oldest methods of conveying bulk materials, with their original design dating back to more than two thousand years. The screw conveyor came into general use a little over a century ago for transfering grains, fine coal and other bulk materials, and continues to serve a unique place in material handling processing. Modern technology has made the screw conveyor one of the most efficient and economical methods of moving bulk materials in process plants.

Choosing your next screw conveyor system is arguably one of the most important stages in designing your system. Our team of material handling experts will consult with you on the optimal type of conveying system, and help you analyze the choice between the different types of screw conveyors to ensure that your individual ingredients are quickly and efficiently transferred in order to transform the raw ingredients into your valuable products.

þ Vertical, Horizontal, & Inclined Screw Augers

þ Heavy-Duty Augers & Flex Screws

þ Shafted/Shaftless Screw Conveyors

þ Integrate with Existing Equipment

þ Olds Elevator Screws Available

þ Customize to Fit Your Needs

Equipment Available

When handling bulk powders and other materials, the process engineering expert are a wide range of bulk and particulate properties that vary enormously. The obvious properties are particle size and size distribution, particle density and, perhaps, particle shape. However, there are many more properties that have an enormous effect on the “handleability” of the material. For example, bulk density, permeability, cohesive bulk strength, moisture content, electrostatic charging, and the list goes on. These properties will significantly influence the performance of mechanical handling equipment.

Email us at info@cmtnc.com or Fill Out the Contact Form Below