Pulverizers, Granulators, and Industrial Crushers

Pulverizers, Granulators, and Industrial Crushers for particle-size reduction, crushing, and lump breaking of materials in process manufacturing

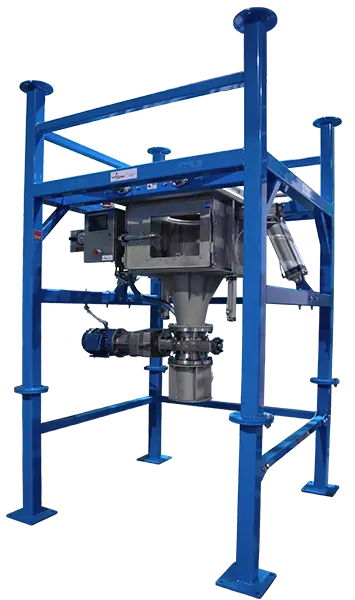

CMT provides ACC Pulverizers, Granulators, Lumpbreakers, and Industrial Crushers for use in Process Manufacturing Applications. Our lumpbreakers use impact to shatter chunks, lumps, and agglomerations formed from friable materials. Reducing large chunks of material to a consistent, free flowing size allows product transport equipment to run at peak efficiency, while increasing the available product surface area which allows reactive processes (mixing, melting, dissolving, etc) to occur more quickly and completely. We specialize in designing custom crushers and variations of our standard equipment for specific applications or processes in order to meet your existing process equipment. CMT offers four different types of sizing equipment: flow-sentry, flow-sizer, flow-smasher, and particle sizer.

Typical Options:

- Construction: Typically available in carbon or stainless steel; Hastelloy, Titanium and other exotic metal construction, polished surfaces, sanitary designs, and abrasion resistant materials for high wear applications also available.

- Seals: Lip seals, Powder Seals, or Packings are standard; single, double, or tandem Mechanical Seals available as required.

- Drives: A variety of gear reduction units, belt/sheave systems, and motor types are available.

- Controls: Jam sensing and reversing controllers are available for jam clearing; torque limiters, limit switches, low speed detectors available.

- Ancillary Equipment: Hoppers, stands, mobile mounting, feed or takeaway systems, special cleaning features as required.

Features and Advantages

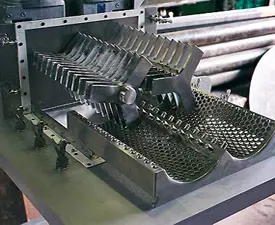

Flow-Sentry

The Flow-Sentry is a fully enclosed crushing device designed to reduce oversize lumps as they travel through a piece of pipe or tube. The Flow-Sentry uses a single set of rotating blades to impact and shatter at close clearance any materials too large to pass between the stationary bars of a sizing grid. Products that pass through the Flow-Sentry are consistent, free-flowing and are often substantially smaller than the slot width of the sizing gird.

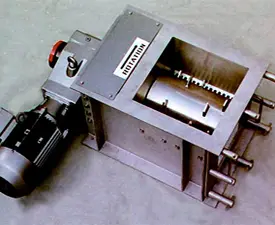

Flow-Sizer

The Flow-Sizer is an economical heavy duty Crusher designed to reduce dry bulk materials to a consistent, fine, free flowing size. It uses a dynamix crushing motion to break up and disperse troublesome oversize materials. Crushing the oversize lumps in the process stream improves efficiency by preventing blockages, by allowing more accurate metering, and by increasing the available surface area of the crushed material, which improves the speed of downstream production processes

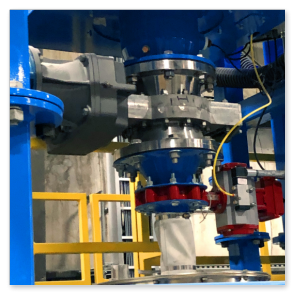

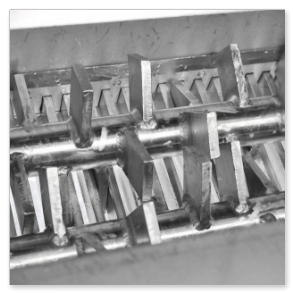

Flow-Smasher

The Flow-Smasher crushers are heavy duty, high torque, high capacity crushing machines capable of reducing large chunks of friable bulk materials to a consistent and free-flowing size. The Flow-Smasher Crushers use a dynamic crushing action to break up and disperse troublesome materials. The Flow-Smasher design is very compact, has incredibly short face to face dimensions, and are available with a variety of Motor and Drive configurations which allow easy integration with ducts, chutes, and conveyor systems, above or below rotary airlocks, in silo discharges, or in bulk bag unloaders.

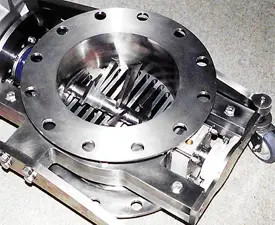

Particle-Sizer

The Particle-Sizer is designed for simple disassembly so that maintenance, cleaning, or replacing a Sizing Cage can be accomplished quickly and easy. The standard Particle-Sizer is offered in 316 SS construction. Special Materials of construction and polished, sanitary designs are offered. The Particle-Sizer is a compact, high output device that can be used by itself with moderately oversize materials or in combination with our other equipment to reduce large "chunks" or "lumps" to a fine powder. The Particle-Sizer uses two high-speed rotary knives to sweep and cut against a series of stationary bars mounted in a "Sizing Cage". This cutting action can reduce materials to 30 mesh or less, depending on material characteristics and the Sizing Cage spacing. Sizing Cages are available in several different slot combinations to provide different output particle size distributions, and they are made to be interchangeable.

Email us at info@cmtnc.com or Fill Out the Contact Form Below