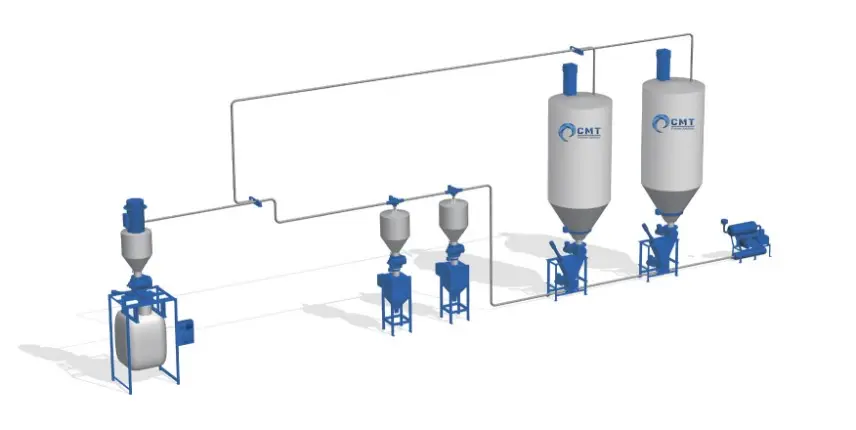

Pneumatic Conveying Systems

Pneumatic Conveying Systems for Material Transfer

Convey Powders, Pellets, and Granules Over Long-Distances with Less Moving Parts

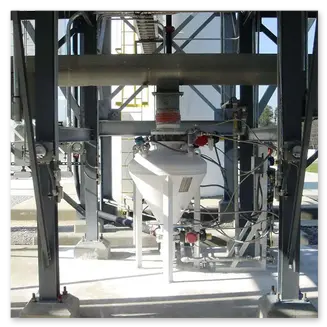

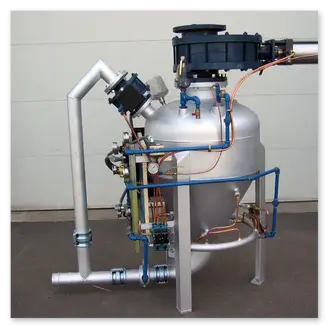

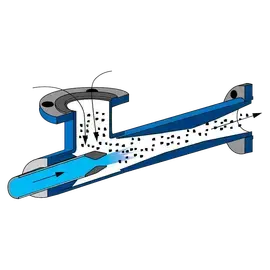

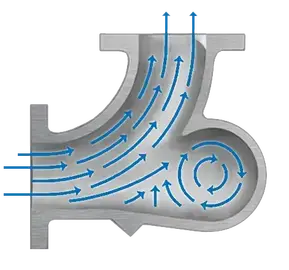

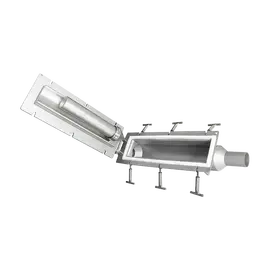

CMT Process Solutions designs and supplies advanced pneumatic conveying systems engineered for the efficient transport of bulk solids and powders. Our product range includes Dense Phase and Dilute Phase Pneumatic Conveyors, Pneumatic Conveying Venturi Eductors, Airslides, and other pressure and vacuum conveying systems. Leveraging extensive material-handling expertise, CMT engineers evaluate each material’s conveying characteristics to determine the optimal conveying mode—dilute or dense phase—and the appropriate gas mover, such as a blower, fan, or compressor.

þ Dense Phase and Dilute Phase

þ Increased Dust Control

þ Increased Efficiency

þ Increased Dust Control

þ Increased Efficiency

þ Increased Layout Flexibility

þ Positive Pressure or Vacuum Systems

þ Integrate with Existing Equipment

Pneumatic Conveving Systems Available

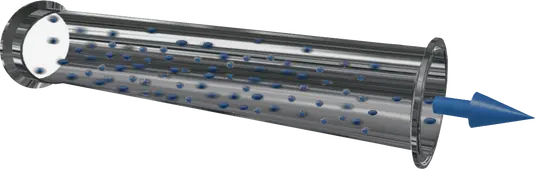

Dilute Phase Conveying Features:

- Air Velocity: High (typically 3,000–8,000 ft/min or 15–35 m/s)

- Pressure: Low (usually under 15 psig for pressure systems)

- Material Concentration: Low — particles are suspended and carried in an air stream

- Flow Behavior: The material is fully entrained in the moving air, resulting in continuous flow.

- Suitable For: Light, non-abrasive, and free-flowing materials such as flour, plastic pellets, sugar, or fine powders.

- Advantages:

- Simple system design and lower initial cost

- Continuous conveying with less risk of plugging

- Flexible routing over long distances

- Limitations:

- Higher wear on pipelines and components

- More energy consumption due to high air velocity

- Not ideal for fragile or abrasive materials

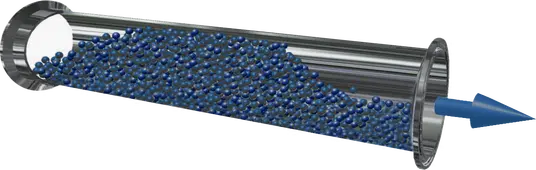

Dense Phase Conveying Features:

- Air Velocity: Low (typically 400–1,500 ft/min or 2–8 m/s)

- Pressure: High (up to 50 psig or more)

- Material Concentration: High — materials move in dense plugs or slugs through the line

- Flow Behavior: The material travels intermittently in batches, pushed by compressed air rather than suspended in it.

- Suitable For: Heavy, abrasive, or fragile materials such as cement, sand, fly ash, or sugar crystals.

- Advantages:

- Minimal material degradation and pipeline wear

- Lower air consumption and dust generation

- Better suited for long-distance or high-capacity transfer

- Limitations:

- More complex design and higher capital cost

- Requires precise control of air pressure and feeding

Components and Spare Parts

Email us at info@cmtnc.com or Fill Out the Contact Form Below