Dilute Phase Pneumatic Conveyors

Transfer Dry Bulk Solids WITH DILUTE PHASE PNEUMATIC CONVEYING

CMT provides a full line of Vacuum and Pressure Dilute Phase Pneumatic Conveying Systems for transferring and handling materials from multiple source points to multiple (or a single) destinations. The flexible pipe routings make it easy to install a new system or upgrade/retrofit your current one. In the right application, dilute phase conveying systems offer a more efficient and longer-lasting alternative to mechanical conveying systems, such as screw conveyors, belt conveyors, vibratory conveyors, aeromechanical conveyors or bucket elevators. There are three main system types: Pressure System, Vacuum System, and Vacuum/Pressure Combination System.

Features and Advantages

- Short (vacuum only), Medium, and Long Distance Conveying

- Easy to install and allows flexibility in routing over long distances

- Low maintenance

- Easy to clean

- Easily integrable with other equipment

- Easy to expand or reduce conveying distance in future modifications

- Multiple material sources

- Multiple material destinations

- Clearing of material from conveying system

- Convey directly from barrel or Gaylord (Vacuum Method Only)

- Convey large capacities over long distances

Overview

Dilute phase pneumatic conveying is a high-velocity system where the product being conveyed is continuously suspended in the air as it is blown or vacuumed through the pipeline. All of the material is transferred and does not accumulate at the bottom of the convey line at any point. To maintain this suspension, air velocity must be kept, most often, between 5,000 ft./min. and 8,000 ft./min. At Carolina Material Technologies our experts underestand that different materials

PRESSURE OPERATED DILUTE PHASE CONVEYING SYSTEMS

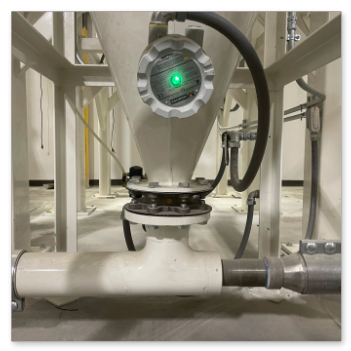

In Dilute Phase Pneumatic Conveying Systems, Pressure operation uses centrifugal fans or PD blowers to send materials across the pipeline. Once it reaches the destination, air and material are separated by a filter or other system. Feeding Systems are used so that materials can enter the pipeline at a greater pressure and the material is then conveyed in suspension or by force at an optimum velocity through the Dilute Phase Conveying System.

Sly Process Systems offers two Pressure Operated Dilute Phase Conveying Systems - Batch Dilute Phase Pressure and Continuous Dilute Phase Pressure. Batch Dilute Phase Pressure Conveying systems allow the material to be transported in distinct batches at the starting point and/or destination. Continuous Dilute Phase Pressure Conveying Systems allow the material to be constantly supplied at the starting point and it arrives continuously at the destination without interruption.

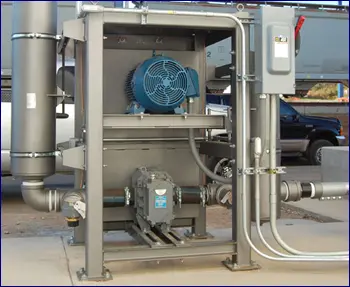

VACUUM OPERATED DILUTE PHASE CONVEYING SYSTEMS

In Dilute Phase Pneumatic Conveying Systems, Vacuum operation uses centrifugal exhausters or PD blowers providing up to 50% vacuum to convey the materials across the pipeline. Once it reaches the destination, air and material are separated with a filter or cyclone. Sly Process Systems offers Continuous Dilute Phase Vacuum conveying systems, and Batch Dilute Phase Vacuum conveying systems. In the case of a continuous dilute phase pneumatic conveying system, the material enters the pipeline directly of through the feeding system and is then suspended in the airflow where it is conveyed at an optimum velocity across the pipeline. Material then enters a receiving vessel on a continuous basis, and is typically discharged to the process through some type of airlock.

In a Batch Dilute Phase Vacuum conveying system, material is conveyed to a receiving vessel in batches where it is discharged through a simple gravity or air operated gate into the process. The vacuum batch conveying method is generally more cost effective as the continuous feeding airlock is eliminated at the discharge point

Dilute Phase Conveying

Flue Gas De-Sulfurization (FGD) System

Conveying Reactant into Gas Steam

Flue Gas De-Sulfurization (FGD) System

Conveying Reactant into Gas Steam

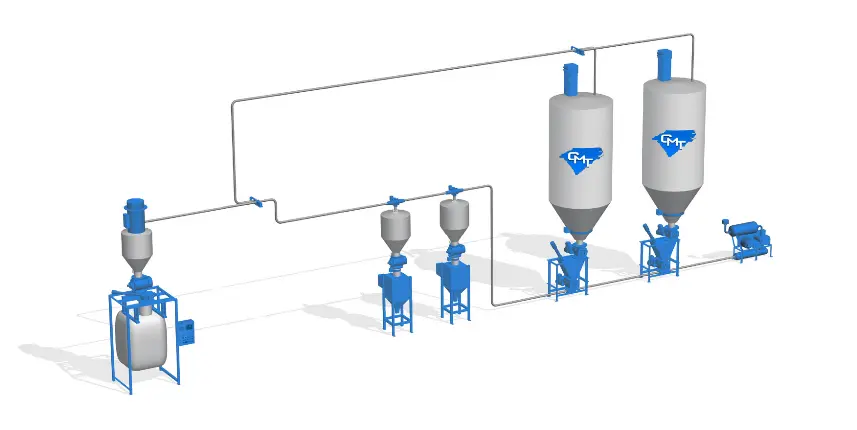

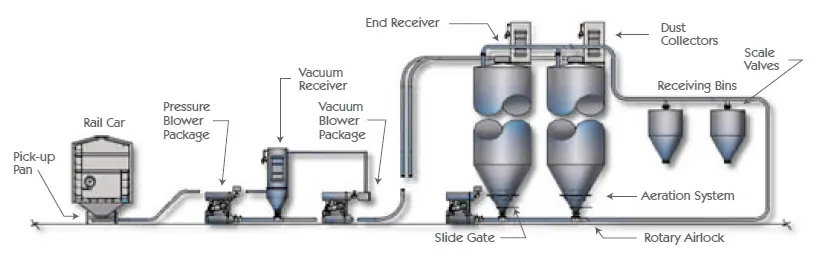

Flow Diagram

In this typical dilute phase system, flowable products are unloaded using a vacuum/pressure unloading system from railcar to storage silos. Products are then conveyed from the silos to in-plant process areas using a separate pressure system. Dilute phase systems are generally used when conveying non-abrasive materials or where high material velocities are not a factor.

Email us at info@cmtnc.com or Fill Out the Contact Form Below