Dry Bulk Tanks and Storage Silo Systems

Dry Bulk Tanks and Storage Silo Systems

Bolted and Welded Storage Silos for Grains, Powders, Liquids, Plastics, and Chemicals

CMT’s storage silos are designed for the reliable storage and handling of dry bulk materials, including grains, cement, coal, plastics, and powders. Engineered to support manufacturing efficiency, safety, and process continuity, our silos provide high-capacity storage within a compact footprint. Gravity-based discharge minimizes reliance on mechanical conveying, while silo design ensures consistent material flow and reduces risks of degradation, contamination, or segregation.

To address varying material characteristics, silos are available in conical, flat-bottom, and mass-flow configurations, with optional flow aids such as vibrators, air pads, or fluidization systems. Integrated safety features—including dust collection, aeration, and explosion protection—meet rigorous industrial and environmental standards. Fabrication options include carbon steel, stainless steel, and specialty alloys, with protective linings and coatings tailored to material compatibility. CMT silos are installed across diverse sectors such as mining and aggregates, plastics, food processing, power generation, chemical processing, and waste treatment, delivering proven performance in demanding operating environments.

þ Bolted and Welded Tanks

þ Dry Bulk Material Storage

þ Chemicals, Powders, and Slurrys

þ Integrate with Conveying Systems

þ Truck/Trailer Receiving & Loading

þ 21 Week Delivery (Fastest in Industry)

Storage Silo Systems & Dry Bulk Tanks

Integrated Storage Systems, Engineered for Reliability

CMT Process Solutions is a specialized storage silo systems integrator delivering comprehensive consultation, engineering design, and project management services for storage tanks and storage silos across both small-scale and large-scale industrial projects. We have completed numerous turnkey installations valued at over $1 million per project, demonstrating proven capability and reliability. Whether your requirement is a single, stand-alone storage silo or a fully integrated storage tank system, CMT provides the expertise and engineered solutions needed to achieve optimal performance and long-term durability.

These tanks are fabricated with steel panels bolted together with custom rubber gaskets separating each panel, making them water-tight. These tanks are fabricated in Stainless or Carbon, and are ideally suited for storage increments of over 150,000 gallons and up to 5,000,000 gallons

Applications: Storage of numerous types of liquids for manufacturing, industrial or commercial use. Storage of numerous bulk materials and dry goods for commercial or industrial needs. Ideal for wastewater, fire protection, biosolids, sludge and more.

Bolted Tanks

These tanks are welded and fabricated from stainless steel and aluminum. Tanks can be constructed with flat bottoms, with hopper bottoms and with elevated structures. Standard one-piece designs are available up to 85 x 15 that can be fabricated in a matter of weeks. Custom and multi-piece tanks can also be designed and fabricated in larger sizes.

Applications: Storage for mining operations, power plants, chemical processing plants, municipal water storage, food processing and production, fire prevention and more.

Welded Tanks

Storage Silo System Integrations

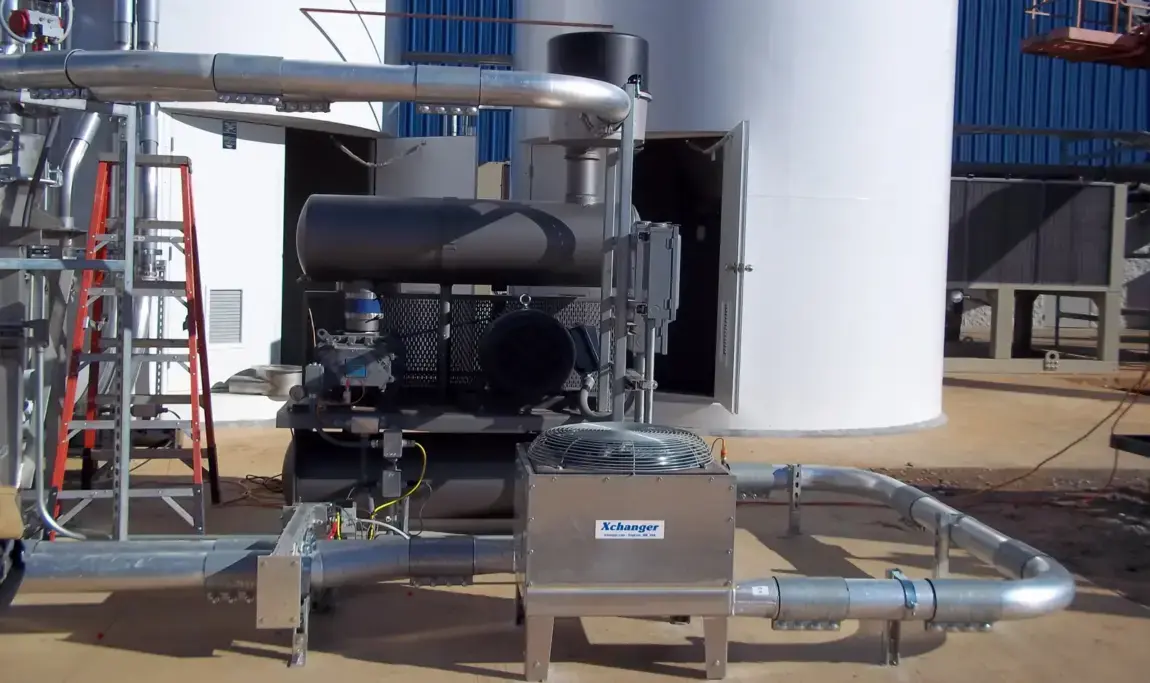

Integration of Pneumatic Conveying Systems into Storage Silo Systems

Pneumatic conveying systems play a critical role in the efficient transfer, handling, and management of dry bulk materials entering or leaving a storage silo. These systems transport materials using controlled airflows (positive pressure, negative pressure, or a combination of both) and seamlessly interface with the silo’s mechanical and structural components to ensure safe, reliable, and dust-free operation.

1. Material Infeed to the Silo

Pneumatic conveying systems transfer material from trucks, railcars, process lines, or upstream equipment directly into the silo. Integration includes:

- Fill lines and conveying pipelines terminating at the silo’s top or side inlets

- Airlocks or rotary valves regulating material entry without loss of conveying pressure

- Receiving filters or vent filters at the silo top to separate conveying air from incoming material

This ensures continuous, controlled loading while preventing over-pressurization or dust emissions.

2. Silo Venting, Filtration & Pressure Protection

Because pneumatic systems influence internal pressure, the silo requires:

-

High-efficiency dust collectors to vent conveying air

-

Pressure and vacuum relief valves to protect the structure

-

Level indicators to prevent overfilling

These subsystems work together to maintain safe airflow and ensure compliance with environmental regulations.

3. Material Discharge from the Silo

Integrated pneumatic conveying can also be used to extract material from the silo and deliver it to downstream processes such as mixing, batching, blending, or packaging.

Key components include:

Key components include:

-

Discharge airlocks / rotary valves for controlled flow

-

Dense-phase or dilute-phase conveying lines depending on material characteristics

-

Blower or vacuum pumps sized for material type and conveying distance

This integration ensures consistent discharge flow rates and prevents bridging or rat-holing inside the silo.

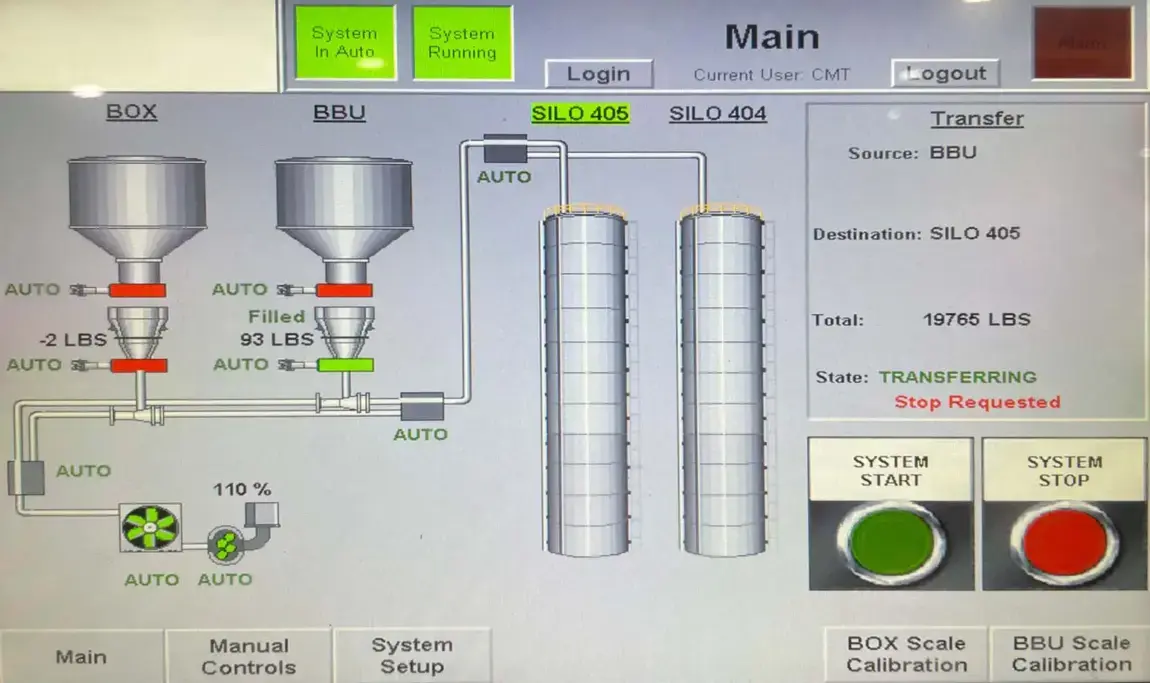

4. Automation & System Control Integration

Smart conveying systems interface with the silo’s plant controls (PLC/HMI) to coordinate:

-

Feed rates

-

Silo filling sequences

-

Pressure setpoints

-

Filter cleaning cycles

-

Safety interlocks

-

Diverter valve positions

This creates a fully synchronized, automated storage and conveying solution.

Related Equipment

Equipment Used in Storage Silo & Pneumatic Conveying Systems

Silo Equipment

-

Silo Structure (Aluminum, Steel, Concrete)

-

Fixed or Fluidized Cone Bottoms

-

Aeration Pads / Fluidizing Systems

-

Vibratory Bin Dischargers

-

Slide Gates & Knife Gates

-

Silo Access Platforms & Ladders

-

Silo Safety Equipment (Handrails, Hatch Covers)

Pneumatic Conveying Equipment

-

Blowers & Compressors (Roots-type, screw, or centrifugal)

-

Vacuum Pumps

-

Rotary Airlock Valves

-

Diverter Valves

-

Conveying Piping & Fittings

-

Flexible Connectors

-

Density Controls for Dense-Phase Systems

-

Transport Vessels / Pressure Pots (dense phase)

-

Pulse Jet & Cartridge Dust Collectors

-

Silo Top Filters / Vent Filters

-

Pressure Relief Valves (PRV)

-

Vacuum Relief Valves (VRV)

Material Discharge Equipment

-

Screw Conveyors & Feeders

-

Slide Gates

-

Vibratory Feeders

-

Loss-in-Weight Feeders

-

Weigh Batching Systems

-

Bulk Bag Unloaders

-

Bin Activators

-

Fluidized Hopper Systems

Material Receiving & Loadout Equipment

-

Truck & Railcar Unloading Stations

-

Blower Packages for Pneumatic Unloading

-

Dust-Free Loading Spouts

-

Weigh Hoppers

-

Surge Bins

-

Truck & Railcar Loadout Systems

Instrumentation & Controls

-

High-Level & Low-Level Sensors

-

Radar or Ultrasonic Level Measurement

-

Pressure Sensors

-

Differential Pressure Switches

-

PLC/HMI Automation Systems

-

SCADA Integration

-

Motor Controls (VFDs)

Our capabilities include:

- Complete specification development, including tank and foundation engineering, structural calculations, and materials selection

- Rapid, accurate equipment and tank quotations

- Approval-stage project drawings delivered within days of order receipt

- Full system integration of auxiliary equipment, interconnecting piping, instrumentation, structural supports, and foundations for a complete turnkey solution

Backed by over 30 years of experience in bulk material handling, CMT Process Solutions delivers engineered systems that meet the highest standards of safety, efficiency, and reliability.

Complete Storage Silo Systems for Powders, Solids, and Liquids

Mineral Storage

Engineered storage solutions for a wide range of minerals, including:

Pebbled Lime, Quick Lime, Hydrated Lime, Diatomaceous Earth, Barite, Perlite, Bentonite, Calcium Carbonate, Alumina, Gypsum, Talc, Sand, Coal, Kaolin Clay, Phosphates, Mineral Salt, Vermiculite, Zeolite, Ore, Feldspar, and other mineral products.

Pebbled Lime, Quick Lime, Hydrated Lime, Diatomaceous Earth, Barite, Perlite, Bentonite, Calcium Carbonate, Alumina, Gypsum, Talc, Sand, Coal, Kaolin Clay, Phosphates, Mineral Salt, Vermiculite, Zeolite, Ore, Feldspar, and other mineral products.

Power Utility Materials

Comprehensive storage system design for utility and power-generation byproducts and fuels:

Fly Ash, Bottom Ash, PRB Coal, Lignite Coal, Lime, Limestone, Powdered Limestone, Pebble Lime, and other dry bulk materials.

Fly Ash, Bottom Ash, PRB Coal, Lignite Coal, Lime, Limestone, Powdered Limestone, Pebble Lime, and other dry bulk materials.

FGD & Limestone Storage Systems

Purpose-engineered storage solutions for:

Lime, Limestone, Powdered Limestone, and FGD byproducts.

Lime, Limestone, Powdered Limestone, and FGD byproducts.

Storage Terminals

Turnkey storage solutions for terminals handling:

All dry bulk materials, including full truck loadout system integration.

All dry bulk materials, including full truck loadout system integration.

Chemical Storage

Engineered systems for a wide array of chemical products:

Carbon Black, Sodium Carbonate, Soda Ash, Fly Ash, Bottom Ash, Cement, Sodium Hydroxide, Urea Prills, Sodium Nitrate, Petroleum Coke, Coal Coke, Magnesium Oxide, Rubber, Detergent, Glass, Stucco, Miscellaneous Acids, Potassium Carbonate (K₂CO₃), Potassium Nitrate (KNO₃), Aluminum Trihydroxide, and more.

Carbon Black, Sodium Carbonate, Soda Ash, Fly Ash, Bottom Ash, Cement, Sodium Hydroxide, Urea Prills, Sodium Nitrate, Petroleum Coke, Coal Coke, Magnesium Oxide, Rubber, Detergent, Glass, Stucco, Miscellaneous Acids, Potassium Carbonate (K₂CO₃), Potassium Nitrate (KNO₃), Aluminum Trihydroxide, and more.

Cement Terminals

Storage and distribution solutions for:

Cement, Fly Ash, Sand, Rock, Aggregate, including complete truck loadout systems.

Cement, Fly Ash, Sand, Rock, Aggregate, including complete truck loadout systems.

Food & Ingredient Storage

Sanitary and food-grade storage designs for:

Flour, Pearl Starch, Sugar, Rice, Salt, Soybean Meal, Cornmeal, Bone Meal, Meat Meal, DDG, Beet Pellets, Buttermilk Solids, Corn Gluten, Dextrose, Farina, Feather Meal, Fish Meal, Flour Premixes, Milk Solids, Middlings, Oyster Meal, Blood Meal, Peanuts, Malt, and more.

Flour, Pearl Starch, Sugar, Rice, Salt, Soybean Meal, Cornmeal, Bone Meal, Meat Meal, DDG, Beet Pellets, Buttermilk Solids, Corn Gluten, Dextrose, Farina, Feather Meal, Fish Meal, Flour Premixes, Milk Solids, Middlings, Oyster Meal, Blood Meal, Peanuts, Malt, and more.

Plastic Resin Storage & Blending

Specialized storage solutions for plastic resins, powders, and regrind materials:

ABS, Nylon, Polycarbonate, Polyethylene, Polyester, Polypropylene, Polystyrene, PVA, PVC (Virgin & Flexible), PET, K-Resin, SAN Resin, Starch, Linear Low PE, Thermoplastic Granules, and other pelletized or powdered plastics.

ABS, Nylon, Polycarbonate, Polyethylene, Polyester, Polypropylene, Polystyrene, PVA, PVC (Virgin & Flexible), PET, K-Resin, SAN Resin, Starch, Linear Low PE, Thermoplastic Granules, and other pelletized or powdered plastics.

Agricultural & Meal Products

Storage solutions for agricultural commodities and processed meals:

Corn, Wheat, Milo, Soybeans, Grain Dust, Guar Beans, Rice Hulls, Coffee Beans, Corn Hulls, Cottonseed, Cocoa Beans, Mustard Seed, Barley, and other grains.

Corn, Wheat, Milo, Soybeans, Grain Dust, Guar Beans, Rice Hulls, Coffee Beans, Corn Hulls, Cottonseed, Cocoa Beans, Mustard Seed, Barley, and other grains.

Biomass Storage

Engineered storage for renewable biomass materials:

Wood Chips, Sawdust, Hogged Fuel, Wood Flour, Charcoal, Sanders Dust, Dry Wood Waste, Starch, and similar fuels.

Wood Chips, Sawdust, Hogged Fuel, Wood Flour, Charcoal, Sanders Dust, Dry Wood Waste, Starch, and similar fuels.

Dry Bulk — Other Applications

Custom storage solutions for specialized and industrial materials:

Kiln Dust, Furnace Dust, Crushed Rock Dust, Roofing Granules, Dewatered Sludge, and more.

Kiln Dust, Furnace Dust, Crushed Rock Dust, Roofing Granules, Dewatered Sludge, and more.

Email us at info@cmtnc.com or Fill Out the Contact Form Below