Cartridge Dust Collectors

A.C.T. Dust Collectors offer the ultimate in air filtration. Whether your application includes welding smoke, grinding dust, cutting table fume, shot blasting, sanding, thermal spray, coating, bulk powder handling or any process that generates dust, we have the solution.

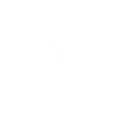

The downward airflow technology maximizes airflow in the collector to assist dust separation. With capabilities up to 100,000 CFM and more, we have the system to maximize your air filtration. The operation of our A.C.T. dust collectors is simple and uses proven technology. The industry best A.C.T. Nano-Elite high efficiency cartridge filters remove 99.9% of the particulate from the air stream. The cleaned air is then directed to the location of your choice, either returned to the facility or exhausted to the environment.

Features and Advantages

The operation of our A.C.T. dust collectors is simple and uses proven technology. The industry best A.C.T. Nano-Elite high efficiency cartridge filters remove 99.9% of the particulate from the air stream. The cleaned air is then directed to the location of your choice, either returned to the facility or exhausted to the environment.

A.C.T. Cartridge Dust Collectors

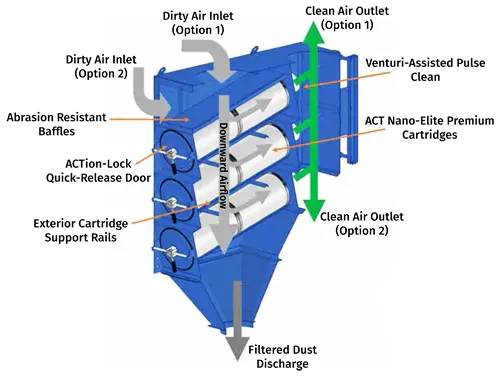

Every A.C.T. Dust Collector is equipped with a venturi-assisted reverse-pulse filter cleaning system and a digital, solid state pulse control panel. The controls utilize an on-board pressure switch allowing on-line, on-demand and down-time cleaning. A weatherproof housing protects the controls for long, trouble-free life.

Perhaps the most popular feature is our exclusive ACTion-Lock Quick-Release filter door. Only aluminum and stainless steel parts are used in the construction of the door cam and mounting rackets for maximum durability in any environment. Simply set the door in place and pull the handle down to lock the cam. Lift the handle for quick-release. When manufacturing this dust collector we eliminated the filter support frame or “yoke” cantilevered off the tube sheet of the collector. By eliminating this, we removed the obstruction that can interfere with the pulse clean process, thereby improving the cartridge cleaning and extending filter life.

STANDARD FEATURES:

• Fully Welded Heavy Construction main unit, constructed of 7 and 10 gauge carbon steel

• Designed, Engineered, and Manufactured in the U.S.A.

• Exclusive ACTion-Lock Quick-Release Filter Door

• A.C.T. Nano-Elite Nano-Fiber High Efficiency Cartridge filters with 254 sq ft media each

• Venturi-Assisted Pulse Clean system with premium Goyen® diaphragms and solenoids

• Exterior Rail Cartridge Supports prevent pulse clean obstruction

• Downward Airflow Technology assists dust particle separation

• Integral Lifting Lugs

• Material Discharge with Sealing Drum Lid

• Digital, Solid State Pulse Control with differential pressure switch for fully automatic cleaning

• Five-Year materials and craftsmanship warranty

OPTIONAL FEATURES:

• Abrasive Inlet Plenum

• Complete line of motor/blowers

• Exhaust Silencers and/or dampers

• Alternate filter media options

• Rotary Airlocks

• Screw Conveyors

• Explosion Vents

• Solenoid Heater Kit

• Custom paint color or coatings

• Multi-Module hoppers

• Steep-Sloped hoppers

• AfterFilter housings

• Bag-in/Bag-out design for hazardous dust

• Stainless Steel construction

Email us at info@cmtnc.com or Fill Out the Contact Form Below