Fox Venturi Eductors

Fox Venturi Eductors for Pneumatic Conveying Solids and Powders

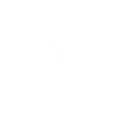

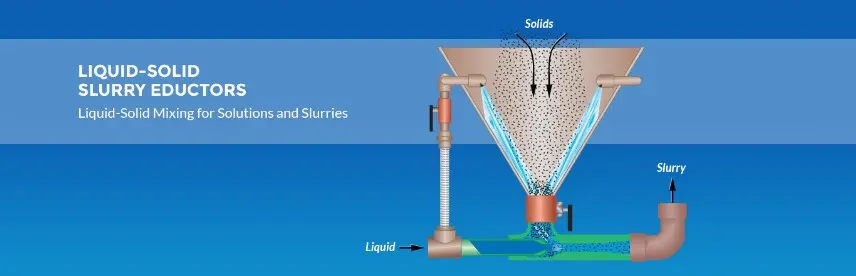

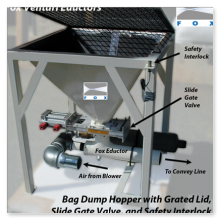

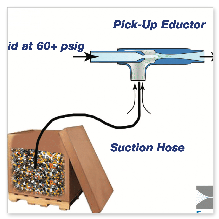

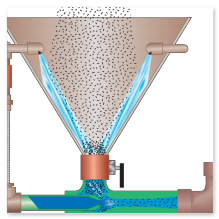

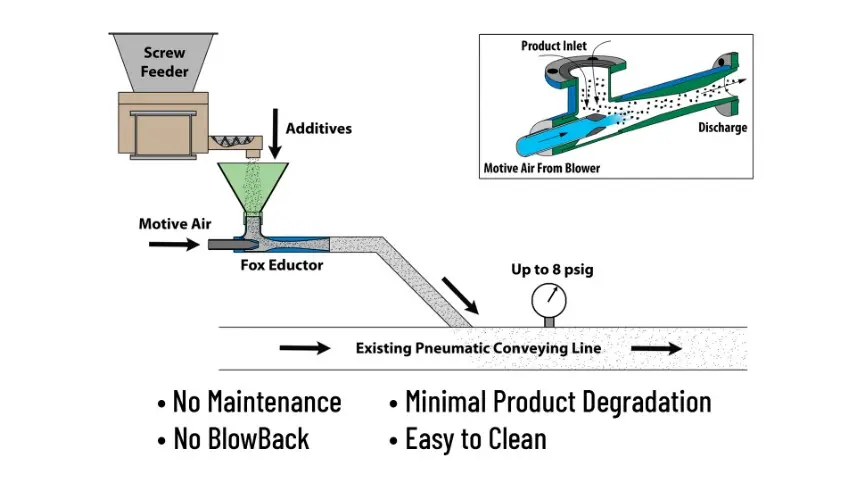

Fox Valves has been providing Venturi Eductor solutions since 1961. Venturi Eductors are used to feed bulk solids - powders, pellets, flakes, and particulates into pressure, dilute-phase pneumatic conveying systems. Venturi Eductors are commonly used in place of rotary valves where airlocks simply cannot perform adequately. Fox Venturi Products has been the leading global supplier of venturi eductors and venturi transport systems for dilute phase pneumatic conveying of powders, pellets, and bulk solids since 1963. Fox Eductors, also referred to as jet pumps, enable the use of low pressure air (below 14 psig or 1 bar) to be used to move powders, pellets, and bulk solids with no moving parts. These venturi eductor systems can be used to convey product at up to 15 tons per hour over distances up to 500 feet.

Venturi Eductors Have No Moving Parts

No Blowback (Seen with Rotary Valves)

Reduce Convey Line Damage

Eliminate Airlock Wear

Reduce Product Damage/Degradation

Avoid Dust Emissions and Leakage

Features and Advantages

Convey powders, pellets, and bulk solids with no moving parts

- Fox Venturi Eductors Have No Moving Parts, providing a low-maintenance solution for feeding your bulk solids. Fox Venturi eductors are a great solution for applications with fine or abrasive products. Replacing your existing rotary airlock valves with venturi eductors makes for simpler, more reliable pneumatic conveying systems. Let CMT ensure maximum reliability and efficiency by incorporating venturi eductors in your system.

- Reduce Dust and Leakage from Blowback, typically seen in most rotary rotary valve applications. Blowback can be especially damaging to your system if the product conveyed is fine or abrasive. Other problems can be observed with free-flowing products, as blowback can cause bridging or other material flow problems, and may even result in an explosion hazard. When installed under dust collector baghouses or screw conveyors, airlocks can be a major source of fugitive dust emissions, which can be eliminated by replacing the rotary valve with a Fox Venturi Eductor.

- Reduce Mechanical Shearing and Product Damage – Eductors greatly reduce shearing, smearing or degradation of materials commonly seen with rotary valves. Fox Venturi Valves greatly reduce damage to your equipment and product, resulting in great return on your investment.

Replace Rotary Valve with a Fox Venturi Eductor

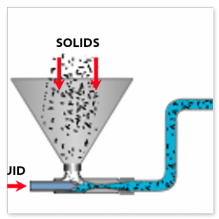

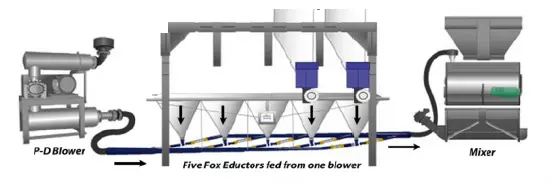

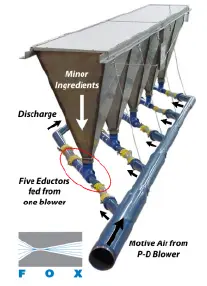

HOW ARE THEY USED IN PNEUMATIC CONVEYING SYSTEMS?

Fox Venturi Eductors are used to introduce bulk solids such as powders, pellets, flakes, and particulates into positive pressure conveying systems. They offer end users and system designers a way to eliminate rotary valves from conveying systems where rotary airlocks/rotary valves simply cannot perform adequately. This often occurs with very fine, abrasive, fragile, or high-temperature solids.

The role of Fox Venturi Eductors In Pneumatic Conveying Systems

Fox Venturi Eductors Have No Moving Parts, providing maintenance-free feeding of powders and other bulk solids. This is a big advantage when the application involves fine or abrasive material. Replacing your inefficient rotary airlocks with venturi eductors guarantees efficiently flowing conveying systems. The design team at Carolina Material Technologies prides itself at finding the most reliable product feeding techniques available. Fox Venturi Eductors certainly provide that.

Why Fox Venturi Eductors?

No Blowback – All rotary airlocks/rotary valves have blowback – also known as fugitive dust or leakage. If the material conveyed is fine or abrasive, blowback can cause wear and tear throughout your system. Blowback can be a problem even with free-flowing materials, causing bridging and other material flow problems, and in worst case scenarios - an explosion hazard. Many plant operators report fugitive dust emissions from airlocks that are installed beneath baghouses, screw conveyors, or dust collectors. These problems were eliminated after a retrofit to Fox Venturi Eductors.

No moving parts highly reduces the chances of Mechanical Shearing or Product Damage. Fox Venturi Eductors minimize the shearing, smearing or degradation of products common with rotary airlocks. Fox Venturi Eductors also provide a safe environment for operators compared to rotary airlocks.

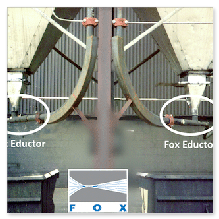

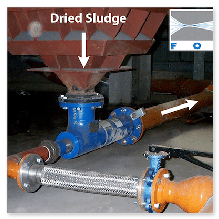

Fox Venturi Photos

Industries Served

Building Products

Phenolic resin and sawdust for chipboard; Gypsum for sheetrock; Pumice powder for grout; Roofing granules;

Foundries

Foundry dust from dust collectors; Inoculants to cupolas; Metal grit from grinding stations; Sand and bond

Cement

CKD at up to 800° F; Portland cement at up to 20,000 lbs/hr; Alternate fuel injection (shredded carpets/plastic/tires//paper; biomass, rice hulls.) Kiln spill at 1600° F

Food

Minor ingredients to mixing/batching (salt, sugar, spices, vitamins, flavorings, etc.); Milk powders from spray dryers; Coffee beans from bulk bags; Powdered tea from screeners; Rice; Breakfast cereal from coating reels; Snack food extrudate from extruders; Frozen peas from IQF; Whole peanuts

Ceramics/Glass

Silica, Glass Frit, Ceramic dust, Mica, Sand/Clay mixes

Hygienic/Diapers

SAP from feeders with uniform flow distribution

Environmental

Activated Carbon, Sodium Bicarbonate, Hydrated Lime, Pulverized Limestone into ducts and stacks; Sorbent injection in fluidized bed boilers for SOx reduction

Minerals/Mines

Hot copper and nickel alloys at 1000°F from calciners; Mica, talc, quartz, and perlite ore from dust collectors; Copper pellets at 400 lbs/ft3 bulk density

Power/Incineration

Coal, coke, and alternative fuels; Additives for inhibiting slag build-up on boiler tubes; sorbents for SOx reduction in CFB's; Activated carbon, lime, calcium carbonate, Trona injection for flue gas desulphurization (FGD)

Plastics

Plastic pellets with reduced angel hair and fines from hundreds of extruders and compounding lines since 1963; 50+ fiberglass filled pellets with Clean-in-place, ceramic-lined wear resistant eductors; Conveying plastic regrind and flakes that jam airlocks in 10 minutes.

Email us at info@cmtnc.com or Fill Out the Contact Form Below